Adhesives Bring a Better Quality of Life

Adhesives and Sealants Make Daily Living Not Only Possible But Better!

We are surrounded by products that are made possible or improved through the innovative use of adhesives and sealants. Take a look around – just about everything is bonded together or sealed securely using adhesives & sealants.

FOOD INDUSTRY

The modern way of food retailing and self-service with its ready-to-eat meals, frozen products and instant foods would be unimaginable without adhesives for manufacturing impermeable packaging materials, such as laminated films, or for hermetically sealing packaging.

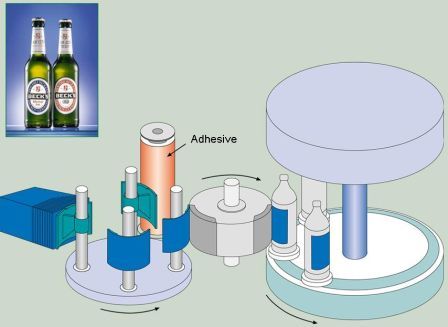

Bottle labeling is used here to exemplify the extent to which seemingly simple “everyday” applications of bonding are in reality “high-tech” solutions: Gluing paper together is child’s play, using either a stick of adhesive or a liquid paper adhesive. The strength is determined by the tear strength of the paper surface and is therefore limited.

There is however something special about bonding labels to bottles: The high operating speeds of the automatic filling machines mean that the adhesive must have high initial tack and the label must be cleanly taken from a magazine. After being rolled onto the usually damp bottle, the label must neither slip nor ripple. And if the bottle ever has to stand in rain or if water condenses on the label, then the labels must remain attached. However, when the empty bottle is returned for reuse at a later date, the label must be able to be easily detached during the rinsing stage before being refilled. A special casein adhesive is able to meet all these requirements: It bonds rapidly, is resistant to water and is soluble in the alkaline washing liquid.

MEDICAL INDUSTRY

Adhesives are used extensively in the medical world, from simple plasters to advanced medical applications.

Adhesives are integral to the production of bandages, dressings and numerous other medical supplies we rely on every day.

Transdermal patches, secured to the skin by adhesives, such as the nicotine patch, permit a controlled delivery of nicotine into the bloodstream to help smokers quit.

HANDICRAFTS

The next time you see a cobbler at work in a quick-repair shop, watch how he glues on a new rubber heel. He removes the old heel from the shoe using a pair of pliers, roughens the joining area and so removes any residues of old adhesive. He then applies a medium viscosity adhesive around the edge of the new heel, over a width of about 1.4 inch. He then presses the heel against the shoe and presses it for a short time in a press. The bond is now intact and the edge can be cleaned up. The reactive adhesive that allows him to work so fast is a cyanoacrylate, also commonly called a superglue. When present as a thin film, this adhesive cures very rapidly in contact with moisture or traces of alkaline substances.

Hobbyists could not create their incredible works of beauty and creativity without the help of adhesives. From wood and paper glue to hot glue and adhesive tapes, the hobbyists of the world rely on easy to use, strong, and versatile adhesives each and every day.

Millions of schoolchildren rely on glue to create and construct projects that help them express themselves and understand the world around them. Adhesives enable creativity and expression for millions and millions of people around the globe!

The above examples have described bonding effects based on adhesion and cohesion mechanisms. In the next example, another feature is considered, namely the ability of the adhesive to dissolve the surface of the substrate.

INDUSTRIAL

The aircraft manufacturing industry provided the key technology impulse for modern bonding technology. The basic need for weight saving was the driving force for new design and construction methods. In modern Airbus aircraft, for example, about 30% of all components are joined using bonding technology.

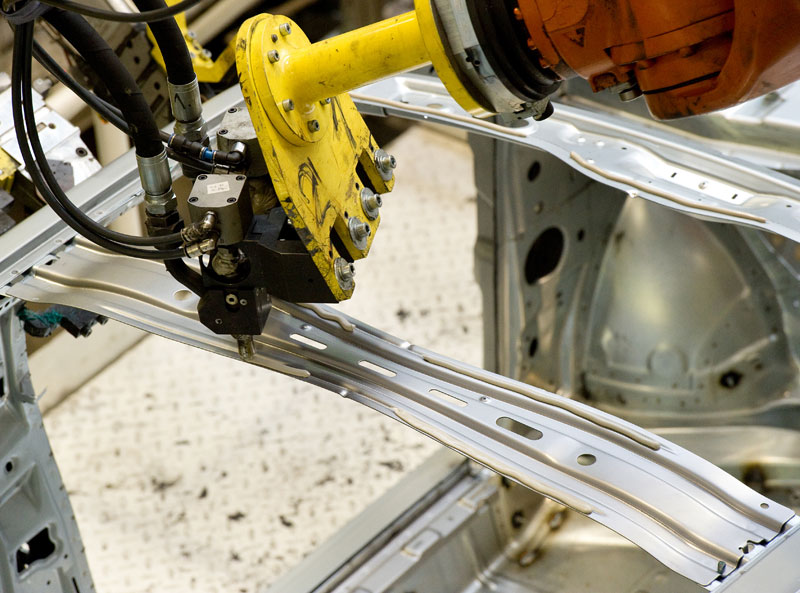

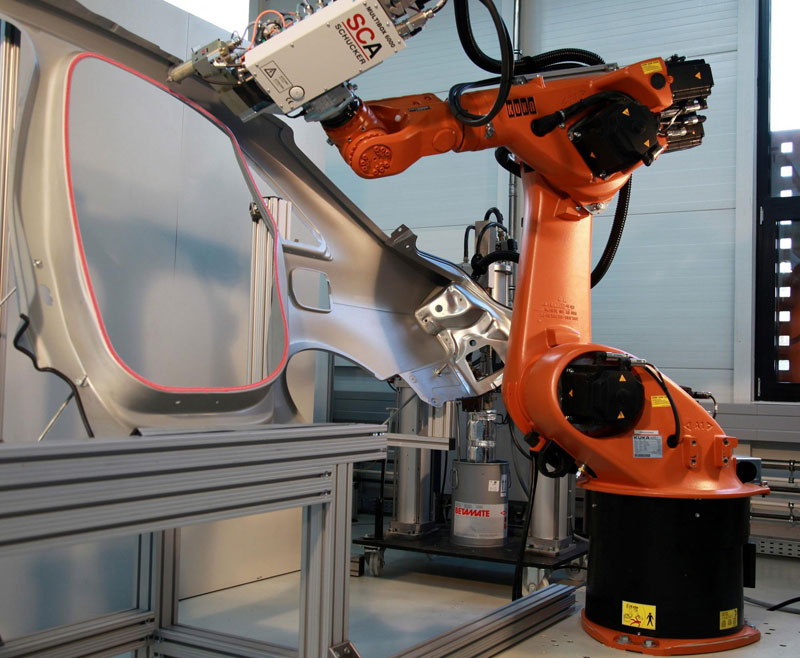

In the car manufacturing industry, classic joining techniques are nowadays used in combination with bonding. In some areas bonding has completely replaced the classic techniques. The increased demand put on engine seals has resulted in bonding technology being used extensively in modern engines, for example for cylinder head seals, in various components for cooling water provision and for the oil sump. Adhesives are also increasingly being used as structural materials. Modern cars contain up to 40 feet (150 m) of bonded joints in the body construction. In addition, bonded front and back windscreens increase the rigidity of the bodies and result in weight reduction. A customized thick-film bonding system dampens vibrations and also improves the heat insulation without using additional materials as is required in conventional designs. Optimized designs with improved driving performance, reduced weight and lower susceptibility to corrosion result in significant energy savings.

Bonding technology plays a special role for lightweight constructions with integrated functions. This means of construction attempts to create products having additional functions, without adding extra components. For example, suitably designed bonded joints between two metals, panes of glass or wooden slats can act as a hinge.

In the area of electronics, the classic joining technique of soldering is being increasingly replaced by bonding, in order for example to connect highly integrated components with each other in a stress-free way and without the need to use excessive heat.

LIMITATIONS

Just like other advanced technologies, the application of adhesives in a production environment necessitates that special processing procedures are adopted. In general, detailed examination of the quality of a bond by non-destructive testing is not possible.

Bonding – like welding and brazing/ soldering – is hence considered to be a so-called special process. When using bonding in a production environment, appropriately high production quality is therefore required, because the product quality is not tested. Degradation mechanisms have to be taken into account when considering the long-term stability of bonded joints. Degradation can reduce the strength of bonds but is generally known to be manageable. One limitation imposed by nature on the use of bonding technology must however not be forgotten: A clear disadvantage of bonding technology compared to other joining techniques is that the resulting bonds only have limited stability to heat due to the fact that adhesives are organic compounds.