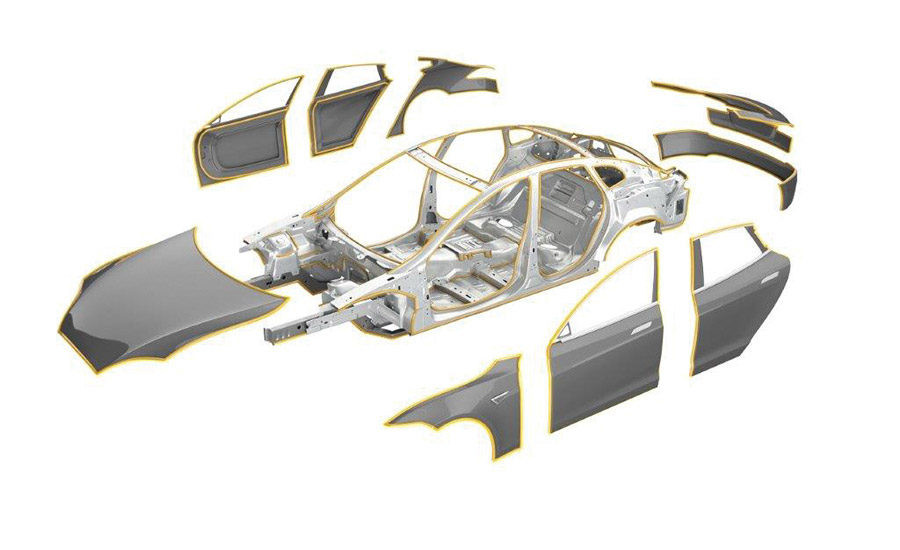

Structural Design

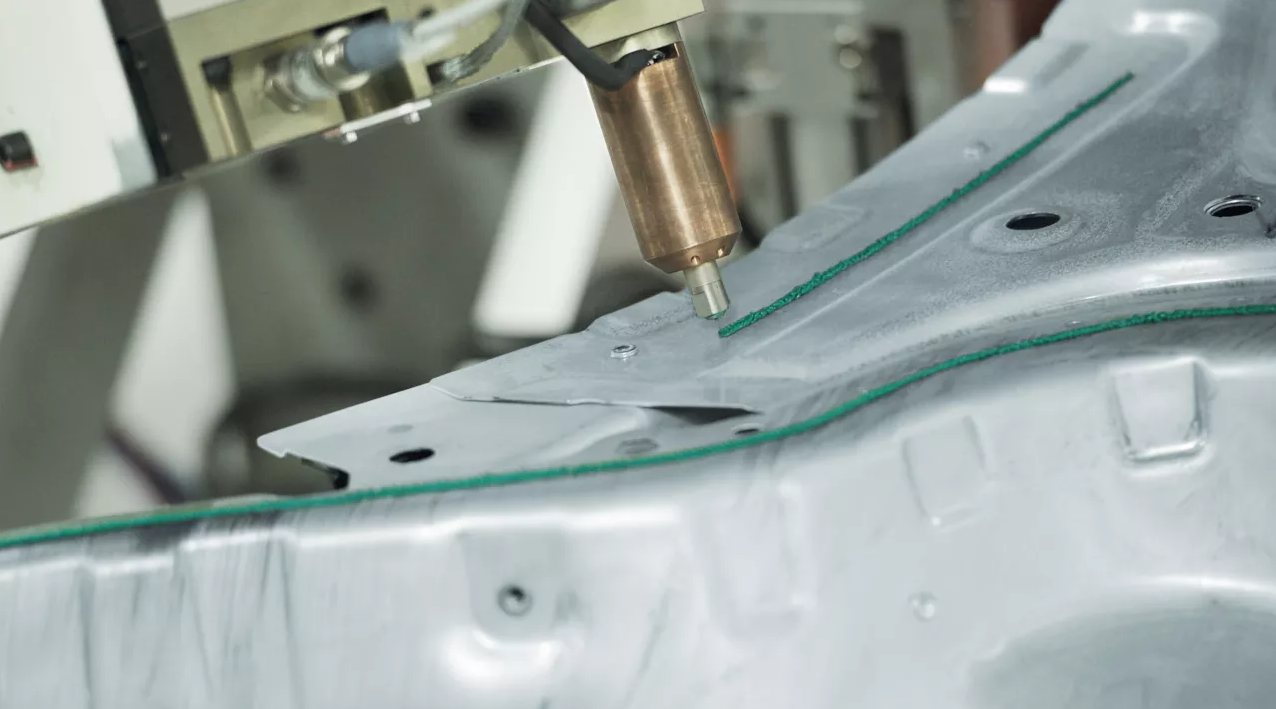

The Structural Bonding Process of Adhesives

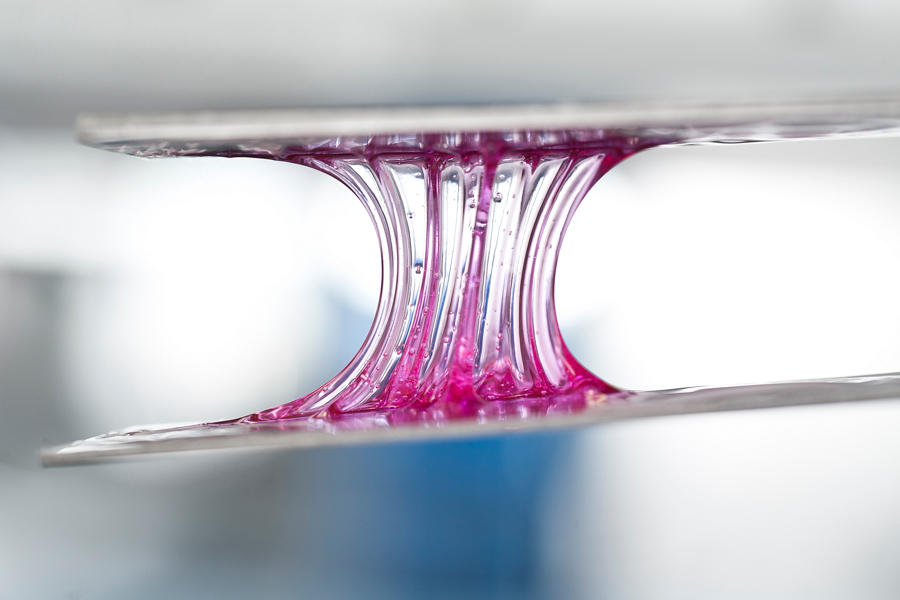

Adhesive bonding is a very complex, multi-layered process with numerous interacting and unexpected factors that may contribute to bond failure. This section is intended to provide the novice reader with a general summary of the structural bonding process.

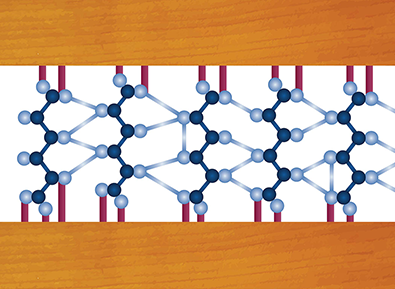

Bonding technology is a systemic joining technique that is based on a variety of interrelated processes. Besides the properties of the adhesive film, substrate materials and the stresses and loads on the joint, the fundamental importance for a bond to be effective is its geometric design. Flaws in bonded structures are a common occurrence because key basic principles of bond design have been neglected. Even in the design phase of a component, special relationships must be taken into account.

The principle requirement on a bond is to transmit forces and be able to withstand the stresses caused by these forces for a long period of time.

When designing bonds, key requirements must be met in order to create a bond having good long-term stability (meaning in particular resistance to moisture)…

Surface Area: a sufficiently large area must be available for bonding and secondly measures must be taken to prevent mechanical loads causing stress peaks in the bond.

Adhesive bonding’s advantages over mechanical methods…

Transfer of high lap shear stresses due to the large bonding areas

Removal of unevenness on material surfaces; greater tolerances possible using gap-filling adhesives.

Prevention of contact corrosion for metal bonds, in contrast to when rivets or screws are used (the adhesive functions as an insulator.)