Sealant Technologies

Today’s adhesives & sealants are classified by bonding mechanism, chemistry or application…

Adhesives and sealants have been used for centuries, with the earliest adhesives and sealants being made of natural materials, such as tree sap, beeswax and tar. Later, processed natural products were used such as animal protein, resin, natural latex.

With the emergence of the chemical industry and synthetic polymers, the range of adhesive and sealant formulations exploded. Today’s adhesives and sealants may be classified in many different ways, such as by cure (bonding) mechanism, chemistry type, and even application (e.g. structural vs. non-structural).

Sealants vs. Adhesives

The main difference between adhesives and sealants is that sealants typically have lower strength and higher elongation than do adhesives. Since the main objective of a sealant is to seal assemblies and joints, sealants need to have sufficient adhesion to the substrates and resistance to environmental conditions to remain bonded over the required life of the assembly.

When sealants are used between substrates having different thermal coefficients of expansion or differing elongation under stress, they need to have adequate flexibility and elongation.

Sealants generally contain inert filler material and are usually formulated with an elastomer to give the required flexibility and elongation. They usually have a paste consistency to allow filling of gaps between substrates. Low shrinkage after application is often required. Many adhesive technologies can be formulated into sealants.

Sealants fall between higher-strength adhesives at one end and extremely low-strength putties and caulks at the other. Putties and caulks, for instance, serve only one function – i.e., to take up space and fill voids. Sealants, on the other hand, despite not having great strength, do convey a number of properties. They seal the substrate at the glue line; they are particularly effective in keeping moisture in or out of the components in which they are used. They provide thermal and acoustical insulation and may serve as fire barriers; sometimes they contain electrical properties. They may also be used for smoothing or filleting.

In short, sealants are often called upon to perform several of these functions at once.

Sealants Serve Three Basic Functions

No matter what the application, a sealant has three basic functions…

It fills a gap between two or more substrates.

It forms a barrier through the physical properties of the sealant itself and by adhesion to the substrate.

It maintains sealing properties for the expected lifetime, service conditions and environments.

The sealant performs these functions by way of correct formulation to achieve specific application and performance properties.

Unlike adhesives, however, there are not many functional alternatives to the sealing process. Soldering or welding can perhaps be used as a sealant in certain instances, depending on the substrates and the relative movement that the substrates will see in service. However, the simplicity and reliability offered by organic elastomers usually make them the clear choice for performing these functions.

SEALANT CLASSES

Sealants are commonly classified by their physical form. The three major classes are:

One-component sealants: Packaged in a cartridge. No special equipment is required to apply one-component sealants; chemical technologies include acrylic solvent-based, butyl solvent-based, latex water-based, silicone and urethane;

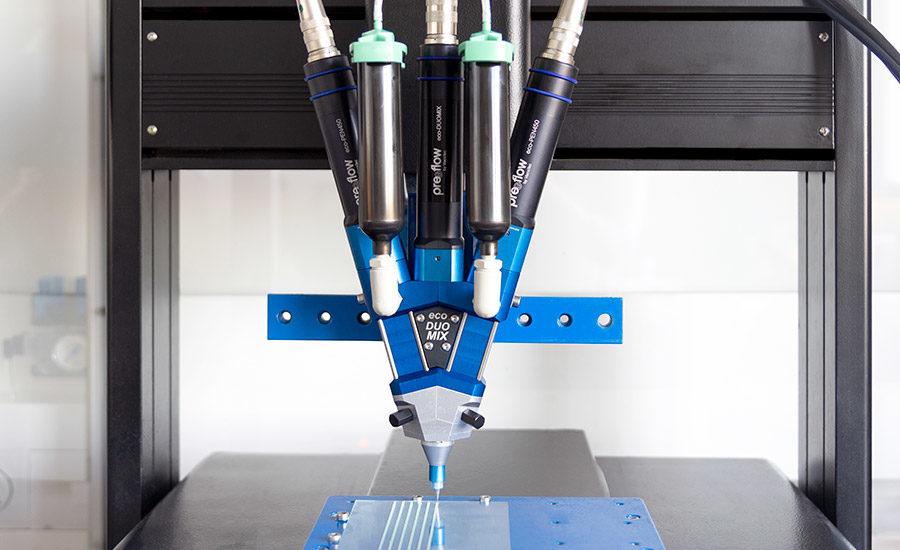

Two-component sealants: Composed of two parts — a base component and an activator component. The activator is typically added to the base component and mixed for a set period of time before application. Two-components require bulk guns and mixing equipment to prepare and apply the sealant, and are typically packaged in separate buckets; chemical technologies include epoxy-penetrating solvent-based (supplied as two-component high-solid compounds), silicone, and urethane;

Sealant tapes: Similar to their PSA Tape “cousins”, sealant tapes are supplied as sealant on a flexible backing; types include butyl and silicone tapes (both preformed shape) and urethane tape (supplied in a compressed state).